Your handling robot just failed. The line is stopped. Production targets are slipping by the hour. The instinct? Order a replacement. Fast. But here’s what the pattern I see repeatedly reveals: that instinct costs semiconductor facilities millions in unnecessary capital expenditure every year. The assumption that broken equals unrepairable—especially for equipment the OEM has declared obsolete—drives decisions that make CFOs wince when the invoices arrive.

The repair advantage in 30 seconds:

- Repair and reconditioning typically costs 40-70% less than full replacement

- Standard equipment exchange delivers within one week versus months for new orders

- Obsolete equipment can often be fully restored by specialist repair companies

- Quality reconditioning includes all moving parts replacement plus rigorous testing protocols

Points covered in this analysis

The Real Cost of Replacing Industrial Equipment

The purchase price is just the beginning. What production managers often miss is the cascade effect that kicks in the moment you commit to full replacement. Lead times for new semiconductor handling equipment run anywhere from 12 to 24 weeks. That is not a typo. During that period, your production capacity takes the hit—or you scramble for temporary workarounds that introduce their own quality risks.

$1million+

hourly downtime cost in semiconductor manufacturing

Those numbers are not abstract. WorkTrek predictive maintenance analysis puts semiconductor production downtime at over one million dollars per hour. Let that sink in. Every day your line sits waiting for new equipment represents a cost that dwarfs any savings you hoped to capture by buying new instead of repairing.

The broader picture matters too. Industry data from Sumitomo estimates unplanned downtime costs manufacturers around fifty billion dollars annually in the United States alone, with equipment failures accounting for roughly 42% of that downtime. The economics of repair versus replacement shift dramatically when you factor in the reality of production continuity.

I have documented hundreds of repair-versus-replace decisions across European and Asian facilities. The pattern is consistent: operations teams underestimate replacement lead times by half, and overestimate repair turnaround by double. The relationship between advances in technology and economic growth creates pressure to stay current, but that pressure often leads to overcapitalisation when strategic repair would serve better.

Repair, Recondition, or Replace: Making the Right Call

Soyons clairs: this is not a binary choice. The most common oversight I encounter is treating equipment decisions as a simple repair-or-replace question when three distinct paths exist. Each serves different operational scenarios, and picking the wrong one costs you either money, time, or both.

Which option fits your situation?

-

Need equipment back within days?

Standard replacement with exchange service delivers a fully reconditioned unit while yours goes for repair. Turnaround within one week.

-

Equipment obsolete but still critical?

Full reconditioning by a specialist. All moving and wear parts replaced, marathon testing, back to original specifications.

-

Technology fundamentally outdated?

New equipment purchase makes sense only when process requirements have genuinely evolved beyond what existing equipment can deliver.

When Standard Replacement Makes Sense

Speed matters most. Standard replacement—exchanging your failed unit for an already-reconditioned one from stock—works when production cannot wait for your specific equipment to go through full repair. Turnaround sits around one week. You ship your failed unit, receive a replacement that has already been tested and certified, and your line resumes.

The trade-off? You get back a functionally equivalent unit, not your exact machine. For most handling robots, load ports, and pre-aligners, this distinction matters less than you might think—specifications match, performance matches, and warranty coverage typically runs six months.

When Full Reconditioning Is Your Best Option

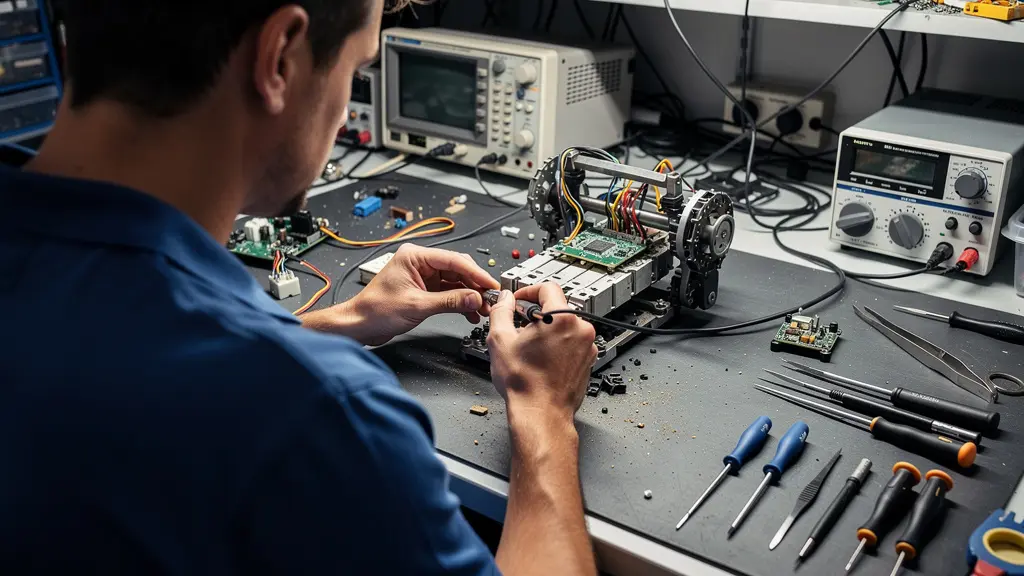

Your equipment, properly restored. Full reconditioning means your specific unit goes through comprehensive overhaul: all moving parts replaced, all wear components renewed, then rigorous testing including marathon handling tests with actual wafer loads and 24-hour repeatability verification. Specialists offering this level of service—you can explore options here—restore equipment to original manufacturer specifications.

Timeline runs longer. Expect two to three weeks versus one week for standard exchange. But you get your exact unit back, fully documented, with warranty coverage. For facilities with specific calibration requirements or integration dependencies, this path often makes most sense.

When New Equipment Is Truly Necessary

Genuine obsolescence exists. When process requirements have evolved—tighter tolerances, different wafer sizes, integration with new automation systems—repair cannot bridge the gap. The question to ask: has my process changed, or just my equipment condition?

If the answer is process change, new equipment makes sense. If the answer is equipment condition, repair almost certainly offers better economics. In my observation of semiconductor facilities, roughly 70% of replacement purchases happen when reconditioning would have served equally well.

| Option | Speed | Cost | Warranty | Best For |

|---|---|---|---|---|

| Standard Replacement | 1 week | Lowest | 6 months typical | Urgent production needs |

| Full Reconditioning | 2-3 weeks | Moderate | 6 months typical | Specific calibration needs |

| New Purchase | 12-24 weeks | Highest | 1-2 years | Technology upgrade required |

What Happens When OEMs Say ‘Obsolete’

The word obsolete gets thrown around too freely. Here is what it actually means when an OEM uses it: they have stopped supporting that product line. It does not mean the equipment cannot be repaired. It means they will not repair it. The distinction costs the industry millions in unnecessary capital expenditure annually.

When obsolete didn’t mean unrepairable

I consulted with a production manager at a UK semiconductor facility in the Midlands facing a critical deadline. Their handling robot had failed—a model the OEM declared obsolete two years prior. The initial assumption? Full machine replacement, with a 12-week lead time quoted.

The friction came from that assumption itself. Nobody questioned whether obsolete meant unrepairable. It took pushing back against the procurement default to explore specialist reconditioning. Ten days later, the unit was back in production with sub-micron accuracy restored. The temporary production line reconfiguration caused minor disruption, but compared to three months of waiting? The lesson I took away: the assumption that obsolete means unrepairable costs this industry far more than it should.

The 2025 semiconductor maintenance report projects the equipment maintenance market reaching 510.4 million dollars this year, growing at 9.3% annually through 2033. That growth reflects the industry’s recognition that keeping existing equipment running makes economic sense—even equipment the original manufacturers have abandoned.

Questions Operations Managers Ask About Equipment Repair

Every decision carries risk. The questions I hear most frequently deserve direct answers, not corporate hedging.

Your equipment repair questions answered

How long does reconditioned equipment last compared to new?

Properly reconditioned equipment with all moving and wear parts replaced performs to original specifications. Longevity depends on operating conditions, not whether the equipment started life new or reconditioned. I have seen reconditioned handling robots run for years beyond their original expected lifespan.

What warranty coverage should you expect on repaired equipment?

Reputable repair specialists provide warranty coverage on reconditioned equipment, typically six months post-delivery. This covers parts and workmanship. Some specialists also offer extended coverage options or service contracts.

Can equipment declared obsolete by the OEM still be repaired?

Yes. Specialist repair companies maintain parts inventories and technical expertise for equipment that OEMs no longer support. Obsolete in OEM terms means they have moved on—it does not mean the equipment cannot be restored to full function.

How do repair specialists ensure quality matches original specs?

Quality-focused operations conduct rigorous testing protocols. This includes marathon handling tests using actual wafer loads and multi-hour repeatability testing to verify consistent performance. Documentation should specify exactly what tests were performed and what results were achieved.

What is the difference between standard replacement and reconditioning?

Standard replacement is an exchange service: you send your failed unit, receive a pre-reconditioned equivalent from stock within about one week. Full reconditioning means your specific unit goes through complete overhaul and returns to you, typically within two to three weeks.

If you are evaluating production equipment decisions, the financial case usually favours exploring repair options first. For facilities also looking to optimise quality verification processes, consider how imaging solutions for quality control integrate with your broader operational efficiency strategy.

The next step for your equipment decision

Your immediate action plan

-

Document your failed or failing equipment: model, age, failure symptoms

-

Get repair quotes before committing to replacement capital expenditure

-

Ask specifically about obsolete equipment support—do not accept OEM obsolescence as final

-

Compare total cost including downtime, not just purchase or repair price

The question to carry forward: when your next piece of kit goes down, will you default to replacement—or will you challenge that assumption first?